ECO - Innovative and adaptive machining technology

With the ECO CNC-machining centre, Reichenbacher Hamuel have utilised all their know-how and experience in high performance machine construction to develop a series that offers the highest levels of flexibility and productivity. The ECO brings together the attributes of reliability, speed and precision synonymous with the name Reichenbacher Hamuel.

The ECO is a self-contained, rigid heavy-duty machining centre. Its vibration-free fixed gantry has two or three supports, depending on the table size and it has one or more aggregate slides (optional at the rear of the gantry). Depending on production demands, the ECO can have one or two machining units that can be controlled by separate NC-channels. The basic machine can be supplied with single or twin tables with the option of additional tables to enable set-up work to be carried out while the machine is in production. This dispenses with the need for reciprocal loading.

Working units

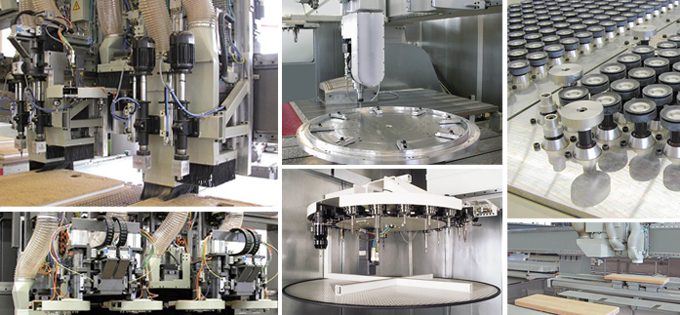

The ECO can be equipped with several working heads, according to the specific requirements.

Routing heads

Vertically mounted routing heads with a performance of 10.0 to 20.0kW, number of revolutions from 1,500 to 40,000rpm, tool fixtures with hollow cone shank HSK 40-F or HSK 63-F (up to 24,000rpm), horizontal routing aggregate, cardanic working head with two numerically controlled machining axes (B- and C-axis) for three-dimensional drilling and routing (5-axis simultaneous machining possible), option: clamping unit at the routing aggregate for the use of additional heads from the tool magazine in any desired angle position in the X-/Y-plane.

Sawing head

Sawing head with NC-turning axis, for saw blades up to Ø 300mm x 6mm, maximum performance up to 5.7kW, number of revolutions 3,000 or 6,000rpm at the drive shaft

Machine table

Plate table or beam table with integrated vacuum and pneumatic system. Different stops, positioning rails and clamping devices extend the functionality. Table lengths 1,600/2,500mm, Table widths 1,600/2,500/3,500mm, Passage 400mm (4-axis machining), maximum 1,100mm (5-axis), Further dimensions on demand.

Tool changer

Automatic tool changing system, magazine plate with 12 or 24 tool places; If more tools are needed, a tool rack with up to 100 tools can be provided.

Following technical consultation with our customers we draw on our process experience and technical knowledge to determine the best combination of units for each individual CNC-machining centre. We can offer support regarding the integration of a CNC machine into any given situation to help customers realise the full potential of the system. More efficient production can be achieved with tailored machining concepts that utilise features such as an automatic selfsetting PIN-table or a programmable beam table with quick-setting clamping devices for production of one-off workpieces or batch production.

The ECO is not an off-the-shelf machine. Your suggestions and production needs are fully considered and incorporated into the planning process prior to preparation of our proposal document. Any special requirements for machine dimensions, table size or the CNC-controller can be evaluated and included in our offer. For us the ECO is not just a machine but part of a system.

Depending on the customer’s needs the heads are adapted to each individual case with automatic tool changers. In case of an increased tool requirement, a tool rack can be provided. Individually customised machining concepts are the basis for efficient production.

For these individual cases customised clamping devices and units are available. A 5-axis machining head on separately movable slides and specific clamping devices are some examples of the variety of functions.