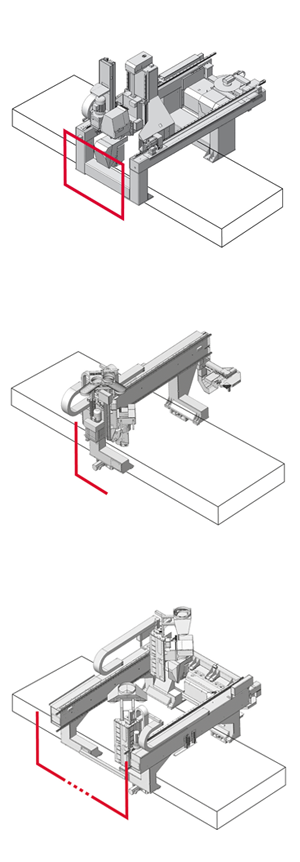

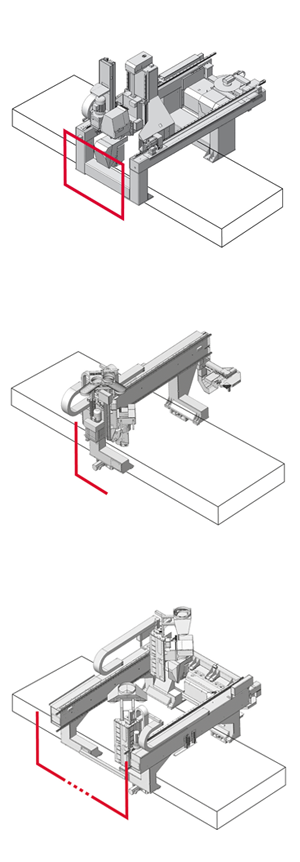

Machines of the VISION series have a machine substructure with a fixed table. The gantry is mounted upon the machine table and carries out the longitudinal motions (X-motions). All head motions are carried out within the enclosed gantry which is equipped with safety bumpers. The main machine components consist of ripped weldments which have an optimal rigidity and/or weight ratio. This allows very high acceleration values.

|

| |

| With the VISION-L up to two independent Y-slides for the heads can be mounted one behind the other. This allows a parallel tool change from two tool magazines and synchronous machining of two workpieces one behind the other – for example when 5-axis fork heads are used. The independent heads are mounted on an L-support in Y-direction and guarantee high availability. |

| |

| The VISION-U offers a lot of varieties for parallel and single machining thanks to the U-shaped gantry. Thus a tool change parallel to machining is possible with two heads from a chain magazine for example – double tools can be omitted. The use of up to two cardanic 5-axis heads with a wide additional equipment guarantees maximum flexibility, such as synchronous machining of two workpieces which are clamped one next to the other and/or one behind the other. |

| |