FLEXIBLE CNC-TECHNOLOGY FOR THE WOODWORKING INDUSTRY

High quality, repeat production and flexibility for small quantities are the typical requirements of most small and medium-sized joinery shops. With the ARTIS X, Reichenbacher Hamuel satisfies the demand for an efficient, flexible CNC-machining centre, which provides high performance at an affordable price.

Short set-up times, a variety of machining options and ease of operation are essential requirements for increased production efficiency in businesses where investment in technology is often limited to a few important purchases. Reichenbacher Hamuel machines are renowned for consistently high output, excellent availability and the highest mechanical reliability. The products are characterised by long operational life with low maintenance requirements.

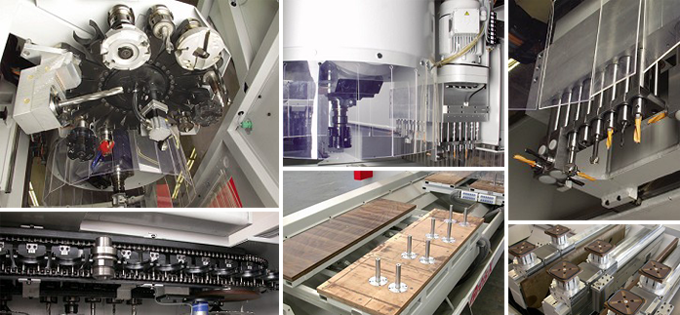

Working head

Performance 14.0/16.0kW, maximum performance from 18,000rpm

Number of revolutions programmable from 500 – 24,000rpm

Tool fixtures with hollow cone shank HSK 63-F

Cardanic working head

B-axis, swivelling range +/- 180°, C-axis, swivelling range +/- 360º

Drilling unit

Multi-spindle drilling unit in L-shape with 12 vertical and 3 horizontal drilling spindles

Multi-spindle drilling unit in L-shape with 25 vertical and horizontal drilling spindles (maximum 7 pieces)

Tool changer

The automatic tool changer system is inside the gantry. A magazine plate with 22 tool places ist integrated, maximum tool diameter 300mm, maximum tool length 240mm, chain magazine with 36 places, maximum tool diameter 300mm.

Additional equipment

Machine table with beams, vacuum system up to 250m3/h (standard 140m3/h), chip removal belt, special clamping devices, laser projection system, barcode reader, modem for telediagnostic, user software for the graphically supported program generation in the stair and furniture production, automatic table optional.

Control

Siemens Sinumerik 840Di

Protection of the entire working area with safety bumpers dispenses with the need for pressure sensitive mats and optimises reciprocal loading possibilities. The ARTIS X is available with 4m or 6m table lengths to suit different application requirements, and both models are equipped with a full 5-axis cardanic working head as standard.

The different table types – plane table, grooved table or beam table – cover every user’s needs. The machine bed is formed as a compact, solid weldment. Exact positioning of the aggregate cantilever in X-axis is by precision ground guides and rack powered by high-performance and maintenance-free servo drives.

The aggregates move within the enclosed gantry – the tools making all the movements. The movable, automatic 15-place tool changer has a maximum outer tool diameter of 300mm, enabling the use of larger tools and standard additional heads.

In addition to the basic equipment of one routing spindle, an optional tool interface (HSK 63-F) and a multi-spindle drilling box with 15 individually controllable spindles are available. The power supply to the 9.0kW spindle (S6), with a performance of 24,000rpm, is permanently controlled to protect the spindle from damage.

The ARTIS X Sprint is equipped with a full 5-axis control – the Siemens 840 Di. Digitally driven axes with absolute measuring systems, together with process optimised control functionality, guarantees the best machining results.