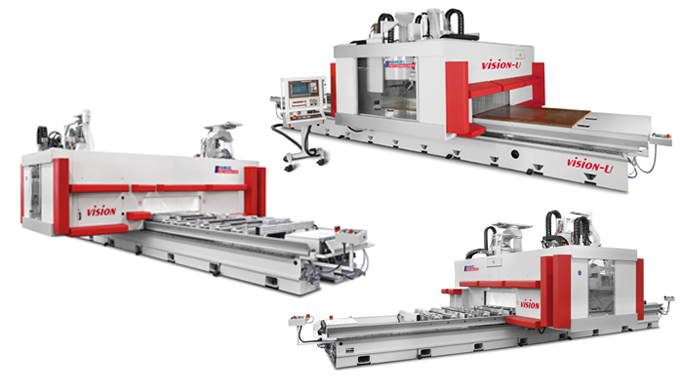

VISION-U/-L - Think of the possibilities

The proven VISION machining centre already has an impressive track record of success in many demanding applications around the world. And, like all Reichenbacher Hamuel machines, the VISION features outstanding machine rigidity – the basis for precision machining. To meet the market challenges of today, and tomorrow, we have developed two new VISION models; the VISION-U and VISION-L.

A major feature of these machines is that they can be supplied with a choice of table dimensions and a wide variety of different heads. These features can be combined for single and parallel machining with up to two independent Y-slides. It is possible to use different working heads next to each other or one behind the other, thanks to the extremely rigid machine construction. For example, two big 5-axis heads with comprehensive additional equipment would cover many different application fields.

Working head

3-axis or 4-axis working head, cardanic 5-axis working head, exchangeable additional

heads, different types of drilling units, sawing heads with different performances

Cardanic working head

Performance 15.0/18.0kW, maximum performance from 10,000rpm or

Performance 20.0/22.0kW, maximum performance from 3,000rpm

Number of revolutions programmable from 1,000 – 24,000rpm

Tool fixtures with hollow cone shank HSK 63-F

B-axis, swivelling range +/- 180°, C-axis, swivelling range +/- 360°

Tool changer

Magazine plate with 12/24 places

Chain magazine with 40/60/80/100/120 places

Additional equipment

Machine table with beams (automatic positioning system optional), vacuum system 250m³/h, chip removal belt, special clamping devices, tool identification system, laser projection system, modem for telediagnostic, barcode reader, user software for the graphically supported program generation in stair and furniture production.

Control

Siemens Sinumerik 810 D / 840 D

Whether employed in the production of furniture, interiors, stairs, doors, round-headed windows, worktops or frames, there are no limits to the machines’ capabilities. There are different table lengths and table systems available. The grooved plate table, with different clamping areas, is the proven universal version most commonly used. The open machine table can be fitted with automatically retractable rollers that transport material into the machine. Material is positioned and pneumatically clamped. The fixed table with pneumatically retractable centring and positioning rails is especially appropriate to the machining of rounded newel posts, steps, strings and handrails. Thanks to its new construction, the table is automatically adjusted for the next workpiece within seconds and setting time is virtually eliminated.

The symmetrically constructed gantry moves above the fixed machine table. The high-performance heads in the gantry can be supplied by one or two magazine plates with 24 tools or by a chain type magazine with up to 60 places. In this way the maximum amount of time can be saved by parallel tool changing. With this high flexibility, companies have an opportunity to save costs in every way, making these machines the best solution for customised component production with short runs.

The mechanical advantage of the cardanic working head allows total motion of the B-axis at any angle between vertical and horizontal, and its unique configuration minimises torque forces when the head is turning and swivelling. Due to the patented technology, the tool tip remains in the same position.