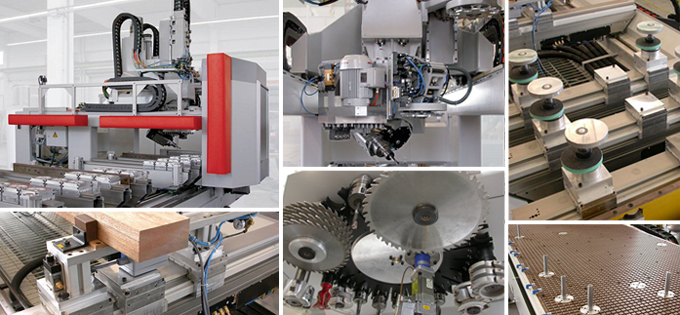

VISION-Premium - More flexibility for extraordinary performance

The new and efficient VISION Premium CNC-machining centre can be equipped with a wide variety of different heads and has applications in all industrial sectors. The VISION Premium offers highquality and flexible processing for both mass production and one off pieces.

Stiff moulded components form the fundamental basis for exceptional production quality. A movable portal is set on top of the rigid machine bed, which ensures superior positioning accuracy. The four-stand design minimises the influence of machining forces and its own weight on the work units.

Machine execution

Grooved table, plane table, beam table (manual and automatic), customised solutions

Working heads

Cardanic 5-axis working heads with up to two additional 3-axis working heads

5-axis working head Performance 15.0kW (S1) / 18.0kW (S6), optional higher performance on request

Revolutions programmable from 500 – 24,000rpm, tool fixture with hollow cone shank HSK 63-F

3-axis working head Performance 15.0kW (S1) / 18.0kW (S6), optional higher performance on request

Revolutions programmable from 500 – 24,000rpm, tool fixture with hollow cone shank HSK 63-F

Tool changer

Tool changer plate with 7 places (moving in X-, Y-, Z- and C-axis)

Tool changer plate with 8 places (moving in X-, Y- and Z-axis)

Tool changer plate with 22 places or chain magazines with 36 / 60 places,

optional with pick-up for tools with a maximum diameter of 450mm.

Multi-spindle drilling head

Multi-spindle drilling head with 19 drilling spindles and free C-orientation, 15 vertical drilling

spindles + 4 horizontal drilling spindles only in connection with 5-axis working head

Specials

Pneumatical stroke and height adjustable extraction hood with directed air circulation

Control

Siemens Sinumerik 840D sl (Solution Line)

Monobloc design with up to four aggregates

Up to four simultaneously arranged units guarantee maximum flexibility with high performance. Highly dynamic servo motors, dual prompted and precise guide elements together with optimised drive adjustment ensure an extraordinary feed performance with ultimate contour accuracy.

Bumper are attached on both sides of the gantry which enable a simple loading – without interfering protective mats or safety fences. This effective casing fulfils all the machine safety requirements for machining centres in the wood processing industry and furthermore ensures a low level of noise and dust emissions.

The unique feature of the head assembly is the 5-axis working head as a central element with interfaces for different tool changers, a drilling head with 19 places, and two slides which can each accommodate a 3-axis routing spindle. The automatic beam table considerably reduces setting times. Other key features of the VISION Premium include quick changeover times, high feed speeds and high dynamics.

Control system with integrated safety principle

The VISION Premium is equipped with the latest generation of control systems, the Sinumerik 840D solution line (sl) from Siemens, whose openness and modular system architecture perfectly matches the design concept of the VISION Premium. The machine is operated and programmed in a time-saving and intuitive manner using a graphic user interface. Above all the control system is able to handle the short reaction times resulting from the high processing speed.