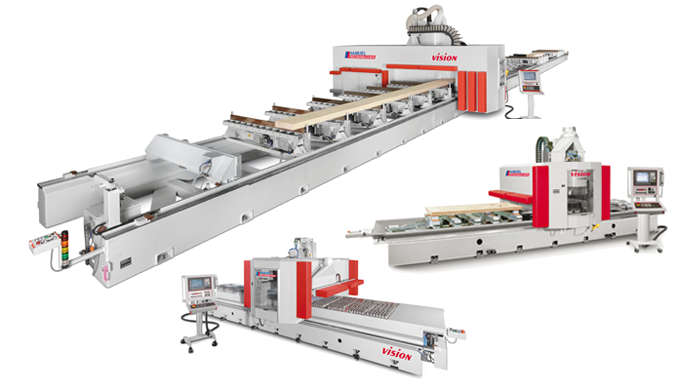

VISION - Workpieces show what the machine can do

Equipped with a cardanic working head, the basic VISION is transformed into the VISION Sprint to provide small and medium-sized joinery and interior design companies with low cost access into 3-dimensional machining. The VISION Sprint unlocks the unique potential that high-speed 5-axis machining offers.

The positioning accuracy of the working aggregate means that the VISION Sprint is excellently suited to the requirements of stair and door production. The two swivelling axes are inclined at 45° to one another and, with optimum tool length, their centre axes intersect at the working point of the tool. By this principle the position of the working point does not change when swivelling in space, which means that no compensation movement in the linear axes is necessary. Thus the working area of the machine is only slightly reduced by the employed tool length when in the horizontal position.

Working head

3-axis or 4-axis working head, cardanic 5-axis working head, exchangeable additional heads, different types of drilling units, sawing heads with different performances

Cardanic working head

Performance 15.0/18.0kW, maximum performance from 10,000rpm. Number of revolutions programmable from 1,000 – 24,000rpm, Tool fixtures with hollow cone shank HSK 63-F, B-axis, swivelling range +/- 180°, C-axis, swivelling range +/- 360°

Tool changer

The automatic tool changing system is placed in the gantry. A magazine plate with 12 places in integrated.

(Magazine plate with 24 places or chain magazine with 40 to 60 places optional). Tool diameter max 300mm / Saw blades up to 350mm

Additional equipment

Machine table with beams (automatic positioning system optional), vacuum system 250m3/h, chip removal belt, special clamping devices, tool identification system, laser projection system, modem for telediagnostic, barcode reader, user software for the graphically supported program generation in stair and furniture production.

Control

Siemens Sinumerik 810 D / 840 D

With the PIN-table, a unique table and clamping system, new levels of versatility in unit production can be achieved. Workpieces are immediately ready for machining and setting time is almost zero. A broad variety of stops, supporting rails and clamping devices are available to create a configuration to match customers’ individual needs. The table can be loaded using sinkable transport rollers. Stops, which are also retracted pneumatically, position the workpiece in longitudinal and transversal directions. Long workpieces may exceed the table (right or left). Once vacuum clamping is activated, machining starts automatically. Control of all machine functions is undertaken by the latest generation of CNC system, the Siemens 840D Powerline. This control technology guarantees efficiency and easy operation. The lower-priced version is the Siemens 810D for adapted processes of 5-axis machining.

12 tools can be accommodated in the automatic tool changing system with magazine plate. The hollow cone shanks, with their high transferable turning moment, are ideally suited to high-speed machining. To increase potential applications, an optional tool changing system with 24 places is available. To further enhance its flexibility, the VISION Sprint can be equipped with a multi-spindle drilling aggregate with individually controllable spindles.

The swivelling range of the cardanic working head allows efficient and economical 5-axis machining without the need for additional heads. Thus the whole capability of the routing spindle is utilised, including horizontal machining. With a directly clamped saw blade, precise cuts can be made in any plane. Saw blades up to a diameter of 350mm define the performance of powerful sawing.